When it comes to excavation work, safety should always be the top priority. Excavations, which involve digging or digging out the earth for various purposes, carry serious risks. So, which of these is known as the greatest danger associated with excavations? The answer is simple: cave-ins. Let’s explore why cave-ins are the biggest threat and how excavation safety can save lives.

The Greatest Danger: Cave-ins

The greatest danger associated with excavations is a cave-in. A cave-in happens when the sides of a trench or excavation collapse, causing dirt and debris to fall on top of the workers. This is a very dangerous situation because it can bury workers under tons of earth.

If the right precautions aren’t taken, cave-ins can be deadly. Sadly, many excavation workers lose their lives each year due to this very reason. That’s why knowing about excavation safety hazards is so important!

Why This Question is Often Asked

You might wonder, why is this question asked so often, especially in OSHA exams, training, and certifications? Well, it’s because the knowledge of excavation hazards is essential for everyone involved in construction and digging projects. When workers and employers understand the greatest danger associated with excavations, they can take proper steps to prevent accidents. This is why proper training and certification are key to ensuring workers’ safety. OSHA’s guidelines are designed to help avoid injuries and fatalities by highlighting the dangers, like cave-ins, and suggesting protective measures.

Real-World Consequences of Excavation Hazards

In the real world, excavation safety hazards can have serious consequences. Imagine a construction site where workers are digging into the ground. If a cave-in happens, the consequences can be severe.

Workers can be trapped under the heavy dirt, and even a small mistake or lack of protection can lead to tragic outcomes.

Apart from cave-ins, there are other dangers to keep in mind, such as falls or hazardous materials like toxic gases and water. But still, cave-ins are the most dangerous threat that workers face on excavation sites.

Other Excavation Hazards

While cave-ins are the most dangerous, there are other excavation safety hazards that workers should be aware of. Falls are another major risk, especially when workers are on the edge of a trench or deep hole.

A small slip or misstep can lead to serious injury. Additionally, toxic gases or water can also create hazards in an excavation. In some areas, gas like methane can leak into the air, making it dangerous to breathe.

Water, whether from rain or underground sources, can fill a trench and make it unstable, leading to the risk of a cave-in. Even though these dangers are serious, none are as deadly as a cave-in.

Why Excavation Safety Saves Lives

Excavation safety isn’t just about following rules; it’s about saving lives. By following safety procedures and making sure that workers have the right equipment, employers can prevent deadly accidents.

For instance, installing trench boxes or using shoring systems can prevent cave-ins by supporting the walls of an excavation.

Workers also need to be trained to spot potential dangers before they become problems. By using protective systems and staying alert to risks, workers can work safely, and tragic accidents can be avoided.

The greatest danger associated with excavations is a cave-in. Excavation work is risky, but with the right safety measures, the risk of cave-ins and other hazards can be reduced.

Safety training, using proper equipment, and following safety guidelines can save lives and prevent accidents.

Remember, excavation safety is not just a set of rules—it’s a lifesaver. So, always stay safe and make sure to protect yourself and your team when working in excavations.

This blog covers the most important aspects of excavation safety, highlighting the dangers of cave-ins and why they are the greatest threat.

By focusing on safety measures and training, we can reduce the risk of accidents and ensure that everyone goes home safely at the end of the day.

Understanding Excavation and Trenching Basics

Excavation and trenching are essential activities in construction and other industries, but they come with significant risks. Understanding the basics of these processes is vital for both workers and employers to ensure safety.

Let’s dive into the core concepts of excavation and trenching, starting with their definitions and key differences.

What Is an Excavation?

Excavation refers to the process of digging, removing, or moving earth, rock, or other materials from a specific location to create space for construction projects.

According to OSHA (Occupational Safety and Health Administration), excavation is any man-made cut, cavity, trench, or depression in the earth’s surface formed by digging, digging, or scooping materials out.

This activity is commonly seen in various construction projects such as building foundations, sewer systems, and road construction.

In construction, an excavation is usually done to prepare the site for structures like foundations, pools, or utilities. It’s a critical part of the groundwork needed before erecting buildings, roads, or other infrastructure.

As part of the excavation process, large equipment such as bulldozers, backhoes, and excavators are often used to move the earth and clear the site.

What is excavation in construction? It’s the first step in preparing the land for a new structure or project. Without proper excavation, the foundation of a building may not be solid, potentially leading to structural instability later on.

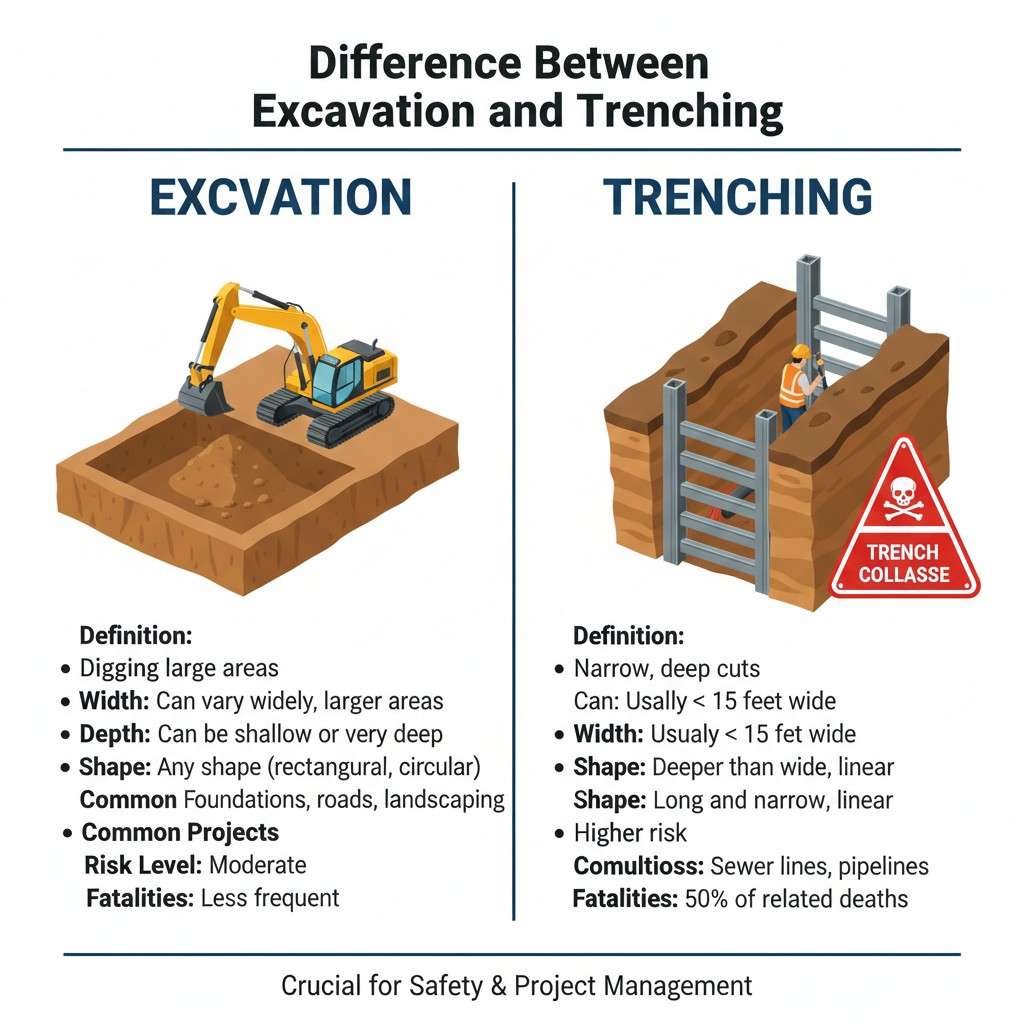

Difference Between Excavation and Trenching

Excavation vs trenching is a common question in construction, and understanding the difference is crucial for safety and project management. Both activities involve digging, but they differ in terms of depth and width.

Below is a comparison table that illustrates the key differences between excavation and trenching:

| Aspect | Excavation | Trenching |

|---|---|---|

| Definition | General process of digging large areas | Narrow, deep cuts in the earth |

| Width | Can vary widely, typically larger areas | Usually less than 15 feet wide |

| Depth | Varies, can be shallow or very deep | Deeper than wide, often several feet deep |

| Shape | May be any shape (rectangular, circular) | Long and narrow, often linear |

| Common Projects | Foundations, roads, landscaping, utilities | Sewer lines, electrical conduits, pipelines |

| Risk Level | Moderate (depends on size and depth) | Higher risk due to deeper, narrower space |

| Fatalities | Less frequent than trench collapses | Trench collapses account for nearly 50% of excavation-related deaths |

Why Trenching Is More Dangerous

Although both excavation and trenching come with risks, trenching safety risks are typically higher. Trenches are much narrower and deeper, which makes them more prone to collapse. A trench collapse can be faster and more deadly than a broader excavation.

Workers in trenches are at a much higher risk of being trapped or buried under tons of soil in the event of a cave-in.

Statistics Overview: According to OSHA, trench collapses account for a significant portion of excavation-related fatalities. In fact, nearly 50% of all excavation-related fatalities are the result of trench collapses.

This highlights the trenching safety risks and the need for additional safety measures when working in trenches compared to general excavation sites.

In summary, while both excavation and trenching involve digging, excavation refers to larger, more general digging projects, while trenching involves narrower and deeper digs, which increase the risks of cave-ins and accidents.

Understanding the key differences between these processes is crucial for ensuring safety and reducing risks during construction projects.

See also HVAC Tune-Up Checklist

What Is the Greatest Danger Associated With Excavations?

Excavation work is essential in construction, but it comes with significant dangers. The greatest danger associated with excavations is a cave-in. A cave-in occurs when the walls of a trench or excavation collapse, burying workers under tons of soil.

This is the leading cause of fatalities in excavation work. In this section, we’ll take a closer look at excavation cave-in hazards and why they are so deadly.

Cave-Ins – The Leading Cause of Excavation Fatalities

A cave-in happens when the walls of an excavation or trench fail and the earth falls in on itself. This is the biggest threat that workers face on excavation sites. The excavation cave-in hazard is a significant concern because it can happen suddenly and without warning.

The speed at which soil can collapse is frighteningly fast, and when a trench caves in, the soil can fall with such force that it buries everything in its path, including workers.

How cave-ins happen: Cave-ins often occur due to the instability of the soil, improper trenching practices, or lack of protective systems. If the walls of a trench or excavation are not properly supported or sloped, the weight of the earth can cause it to give way.

Over time, vibrations from nearby equipment, rain, or even changes in temperature can weaken the soil, making it more likely to collapse.

Speed and force of collapsing soil: When a trench collapses, the soil falls quickly, often within seconds. The force of the soil can be overwhelming, and workers standing in or near the trench have no time to react. The soil’s weight and speed make escape nearly impossible, even for experienced workers.

Why workers can’t escape: Once a cave-in occurs, workers often have no chance of escaping. The soil may bury them so quickly that they are trapped and unable to move.

The force of the collapse can also crush or suffocate workers, making it extremely difficult for them to survive. The rapid nature of a trench collapse means there’s very little time for workers to react or escape the danger.

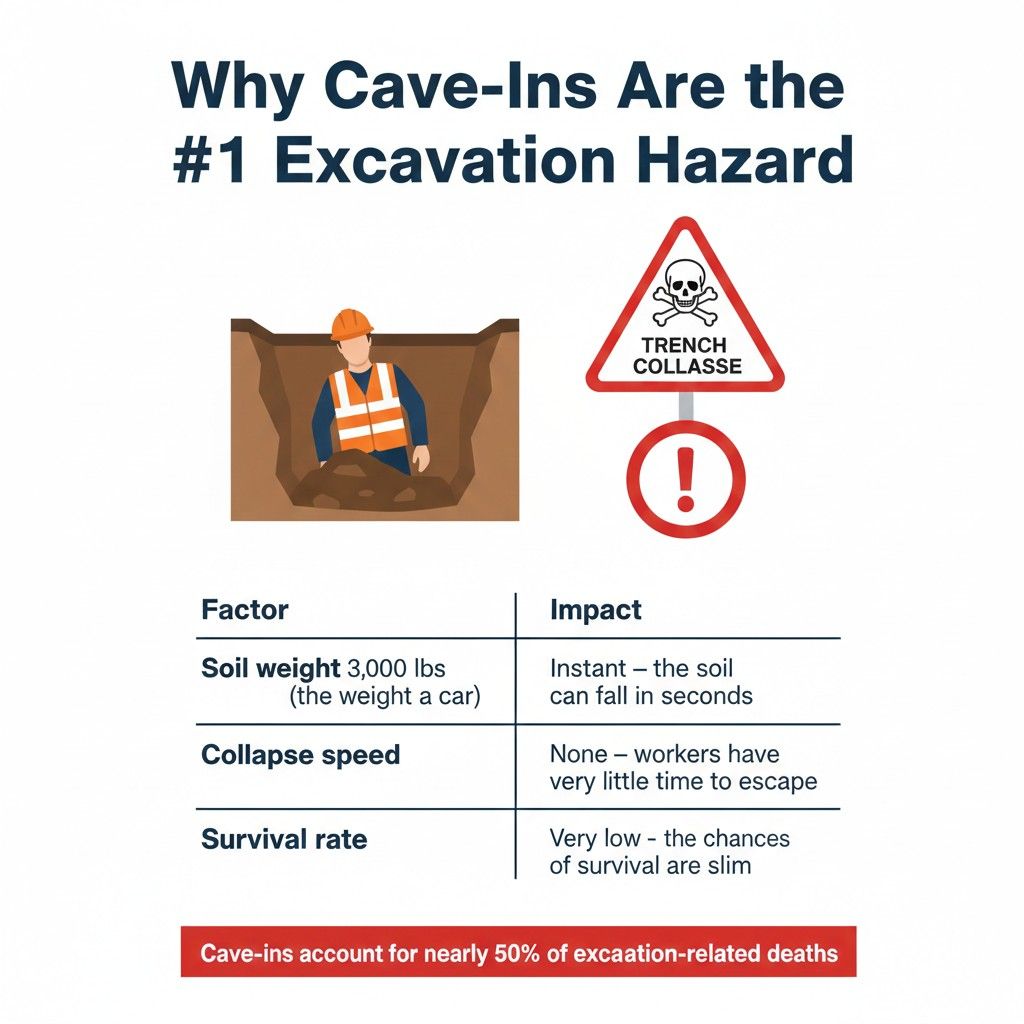

Why Cave-Ins Are So Deadly

A trench cave-in risk is more than just the collapse of the trench—it’s a fight against nature. The soil can weigh thousands of pounds, and when it falls, it can cause serious injuries or fatalities.

Weight of soil explained simply: Soil is surprisingly heavy, and when it collapses, it can crush anything in its path. For example, one cubic yard of dirt can weigh more than 3,000 pounds (about the same as a car!). When a trench collapses, the weight of the soil can quickly bury workers, making escape almost impossible.

Suffocation and crushing risks: Workers trapped in a cave-in are at risk of suffocating because the soil can fill their lungs with dirt. The pressure of the soil can also crush vital organs, especially the chest and lungs. Even if workers are not immediately buried, the weight of the soil pressing down can make it nearly impossible for them to breathe or move.

Rescue difficulty: The challenge of rescuing someone trapped in a trench collapse is immense. It can take hours, or even days, to free a worker safely. During this time, the trapped worker’s chances of survival decrease rapidly, especially if they’ve suffered from crushing injuries or suffocation. Moreover, the risk of another collapse during the rescue operation makes this type of work even more dangerous.

Why Cave-Ins Are the #1 Excavation Hazard

The table below explains why cave-ins are the most dangerous risk when it comes to excavation work.

| Factor | Impact |

|---|---|

| Soil weight | Can exceed 3,000 lbs (the weight of a car) |

| Collapse speed | Instant – the soil can fall in seconds |

| Escape time | None – workers have very little time to escape |

| Survival rate | Very low – the chances of survival are slim |

As the table shows, the combination of the massive weight of the soil, the speed at which it falls, and the lack of time to escape all contribute to the deadly nature of cave-ins.

With the excavation cave-in hazard being so extreme, it’s no wonder that it’s considered the greatest danger on excavation sites.

In conclusion, cave-ins are the greatest danger associated with excavations, responsible for many fatalities each year. The speed and force of collapsing soil make this risk particularly deadly, and the chances of survival are low.

It’s crucial for workers to understand these risks and for employers to implement strong safety measures, such as trench boxes and shoring systems, to prevent cave-ins and protect workers. Excavation safety is not just about following regulations—it’s about saving lives.

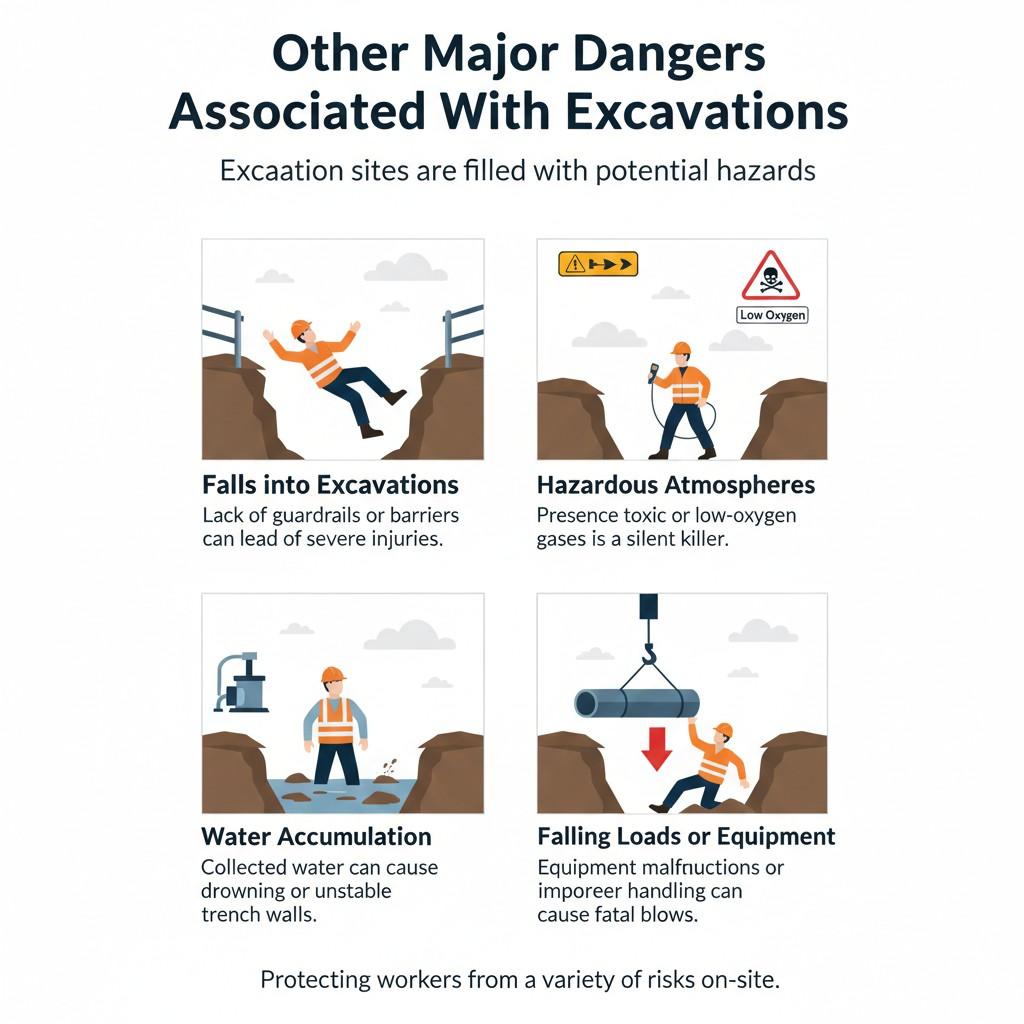

Other Major Dangers Associated With Excavations

Excavation sites are filled with potential hazards, and while cave-ins are the most deadly risk, they are far from the only ones. Excavation workers face a variety of dangers that can result in serious injuries or fatalities.

In this section, we will explore other major dangers associated with excavations, including falls into excavations, hazardous atmospheres, water accumulation, and falling loads or equipment.

Falls Into Excavations

Excavation fall hazards are a significant concern at construction sites. When workers are near or around excavations, the risk of falling into the excavation is high, especially if safety measures are not in place.

Open edges: One of the most common causes of falls into excavations is unprotected or open edges. Trenches and excavation sites often have deep, vertical sides, which can be difficult to see or navigate, especially if there is no safety barrier to mark the edges.

Poor barriers: Proper barriers and guardrails are essential to prevent workers from falling into open excavations. If barriers are weak, improperly installed, or missing altogether, the risk of falls increases dramatically. Workers walking too close to the edge may accidentally lose their balance or step into the trench, leading to falls.

Night visibility: Excavations can pose an even greater risk at night or in low-light conditions. Poor visibility makes it harder for workers to see the edges of an excavation, increasing the likelihood of falls. Proper lighting and reflective markers are crucial for night-time safety to ensure that workers can identify potential fall hazards.

To prevent falls into excavations, employers must implement fall protection excavation measures, such as installing guardrails, barriers, or warning signs around open trenches. Additionally, workers should wear proper footwear and be mindful of their surroundings.

Hazardous Atmospheres

Excavations also present excavation confined space hazards, especially when workers are working below ground level. The atmosphere within an excavation can become dangerous if it contains low oxygen levels or toxic gases.

Oxygen deficiency: When excavations are deep or poorly ventilated, oxygen levels can drop. Workers exposed to low oxygen levels may experience dizziness, fainting, or even suffocation. Lack of proper ventilation is a key contributor to oxygen deficiency.

Toxic gases: Some excavations, especially those near sewer lines, underground utilities, or industrial sites, may contain dangerous toxic gases. These gases include hydrogen sulfide, methane, and other harmful substances. Breathing in toxic gases can lead to poisoning, unconsciousness, or even death.

Carbon monoxide: The presence of carbon monoxide in an excavation is another significant hazard. This gas is colorless and odorless, making it nearly impossible to detect without proper equipment. Carbon monoxide can be produced by engines running in or near the excavation, such as those of trucks, generators, or pumps. Prolonged exposure can result in dizziness, nausea, and eventually, death.

Workers must be trained to recognize toxic gases in excavations, and employers should ensure that proper ventilation, gas detectors, and safety measures are in place to prevent exposure to harmful gases and low oxygen levels.

Water Accumulation and Flooding

Water accumulation is another serious hazard that can lead to excavation accidents.

Rain: Heavy rain can quickly fill an excavation with water, making it dangerous for workers. Wet conditions not only increase the risk of cave-ins, but they can also create slippery surfaces, leading to falls or equipment malfunctions. Rainwater runoff can also erode the edges of a trench, causing it to collapse.

Groundwater: Some excavations are affected by groundwater, which can seep into trenches and cause flooding. When groundwater enters an excavation, it can create unstable conditions, increasing the likelihood of a trench collapse. Pumping systems may be required to manage this water, but if not properly installed or maintained, groundwater can pose significant risks.

Burst pipes: A burst pipe, whether it’s a water main or sewage line, can also flood an excavation. The force of the water from a broken pipe can wash away the soil, creating dangerous conditions and increasing the risk of cave-ins. Workers should be cautious when excavating near existing utilities to avoid damaging pipes that may cause sudden flooding.

Falling Loads and Equipment

Heavy machinery and equipment used at excavation sites also present significant risks to workers.

Excavators: Excavators and other heavy machinery are essential for digging and moving materials at excavation sites.

However, these machines can pose dangers if not properly operated or if workers are in the wrong place at the wrong time. Excavator buckets or other equipment can accidentally swing or fall, striking workers or causing injuries.

Spoil piles: When soil and debris are removed from an excavation, they are often piled up next to the trench in spoil piles.

These piles can shift or collapse if not properly managed. Workers may be injured if the spoil pile collapses or if they are working too close to the pile.

Moving vehicles: Excavation sites often have moving vehicles, such as dump trucks and loaders, transporting materials. These vehicles pose a significant risk to workers who may be in the way.

Accidents involving moving vehicles can result in severe injuries, especially if workers are not properly trained to avoid moving machinery.

To reduce these risks, employers must implement proper training, use spotters when necessary, and ensure that spoil piles are properly managed and away from active work zones.

Additionally, workers should be aware of moving equipment and always stay clear of dangerous areas.

Excavation sites are filled with multiple hazards, each of which requires attention and proactive measures to keep workers safe. Beyond cave-ins, the dangers of falls into excavations, hazardous atmospheres, water accumulation, and falling loads or equipment all contribute to the risks faced by workers.

By implementing safety measures such as fall protection, proper ventilation, water management, and equipment safety protocols, the likelihood of accidents and fatalities can be reduced. Excavation safety is essential, and workers and employers must remain vigilant to avoid these major dangers.

Why Cave-Ins Happen So Often

Cave-ins are the most significant hazard in excavation work, and they occur far too frequently. Understanding why cave-ins happen is key to preventing them and ensuring excavation safety.

Several factors contribute to the likelihood of a cave-in, including the type of soil, environmental conditions, and human errors. In this section, we’ll examine the primary reasons why cave-ins occur so often.

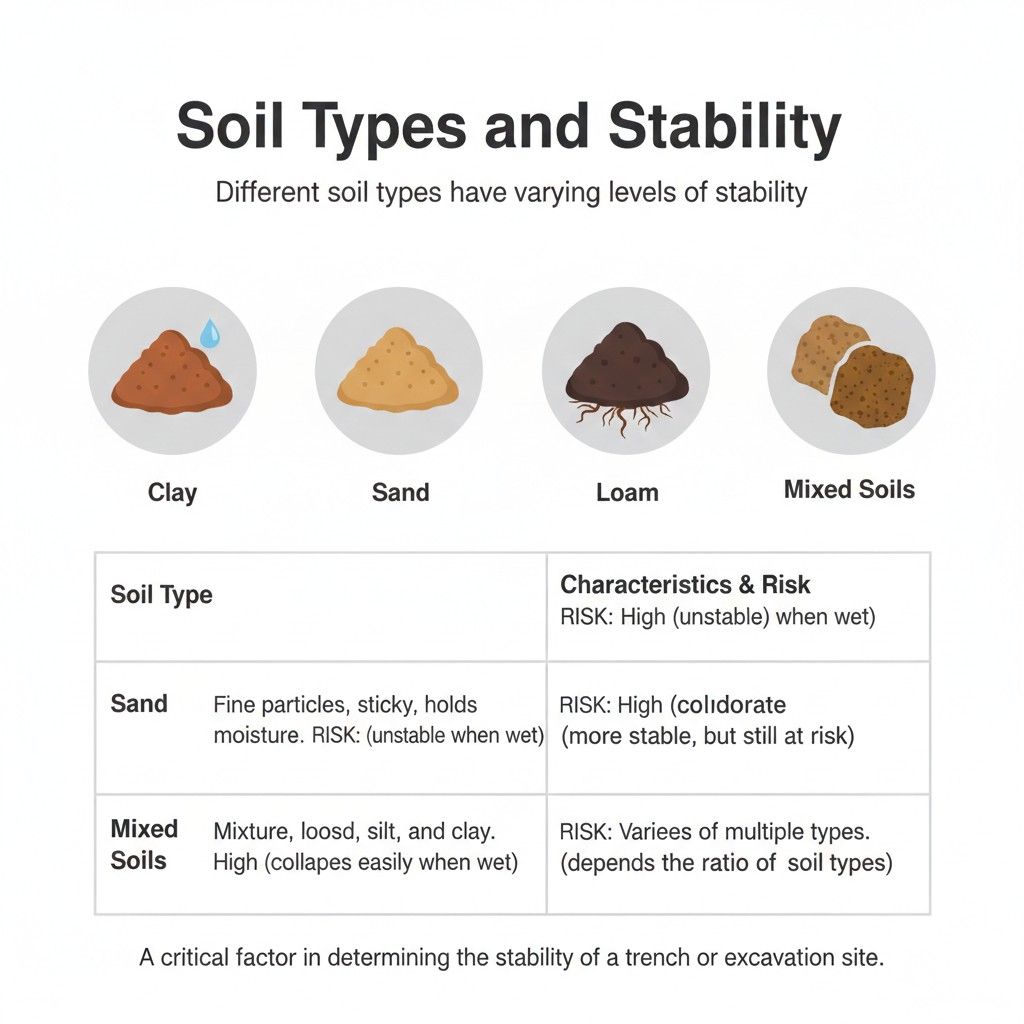

Soil Types and Stability

Soil types excavation safety is a critical factor in determining the stability of a trench or excavation site. Different types of soil have varying levels of stability, which can affect how easily a trench or excavation collapses.

| Soil Type | Characteristics | Risk of Cave-In |

|---|---|---|

| Clay | Fine particles, sticky, holds moisture | High – can be unstable when wet |

| Sand | Granular, loose, drains easily | High – collapses easily in wet conditions |

| Loam | Mixture of sand, silt, and clay, holds moisture well | Moderate – more stable, but still at risk |

| Mixed Soils | Combination of multiple types | Varies – depends on the ratio of soil types |

- Clay: Clay is heavy and sticky, which can make it seem stable, but when wet, it becomes slippery and prone to collapsing. Wet clay has a higher risk of cave-ins due to its instability when saturated with water.

- Sand: Sand has a much higher risk of collapse compared to other soil types. It’s loose and granular, and it can easily shift or collapse, especially in wet conditions. Sand doesn’t hold its shape well without support, making it a prime candidate for cave-ins.

- Loam: Loam is a more balanced soil type and tends to be more stable than clay or sand. However, it still presents a risk in certain conditions, particularly if there’s a significant amount of moisture or if the trench is too deep.

- Mixed Soils: Excavations involving mixed soils are tricky because the trench may have areas of stability and other areas that are unstable. The risk of cave-ins can vary greatly, depending on the specific mix of soil types.

When excavating in unstable soil excavation areas like loose sand or wet clay, the risks of cave-ins increase dramatically. Soil testing and proper support systems are critical in these cases to prevent collapse.

Environmental Factors

Certain environmental factors can significantly increase the likelihood of a cave-in during excavation work.

- Rain: Heavy rainfall can cause soil to become saturated and weaken the walls of a trench, increasing the chance of collapse. Water can erode the trench’s edges, making the soil less stable and more prone to sliding.

- Vibration: Vibrations from nearby construction equipment, vehicles, or machinery can disturb the soil in and around an excavation, increasing the risk of cave-ins. Vibrations can make unstable soils shift or loosen, leading to a sudden collapse.

- Nearby Traffic: Traffic, whether it’s pedestrian or vehicle movement near the excavation, can cause vibrations or shifts in the soil. In addition, vehicles and heavy equipment passing near the excavation site can apply additional pressure on the trench, destabilizing the walls and increasing the risk of collapse.

These environmental factors make excavation work particularly dangerous when the weather is poor or when nearby activity interferes with the stability of the soil.

Workers must remain aware of these risks and take necessary precautions, such as installing proper support systems and monitoring for potential hazards.

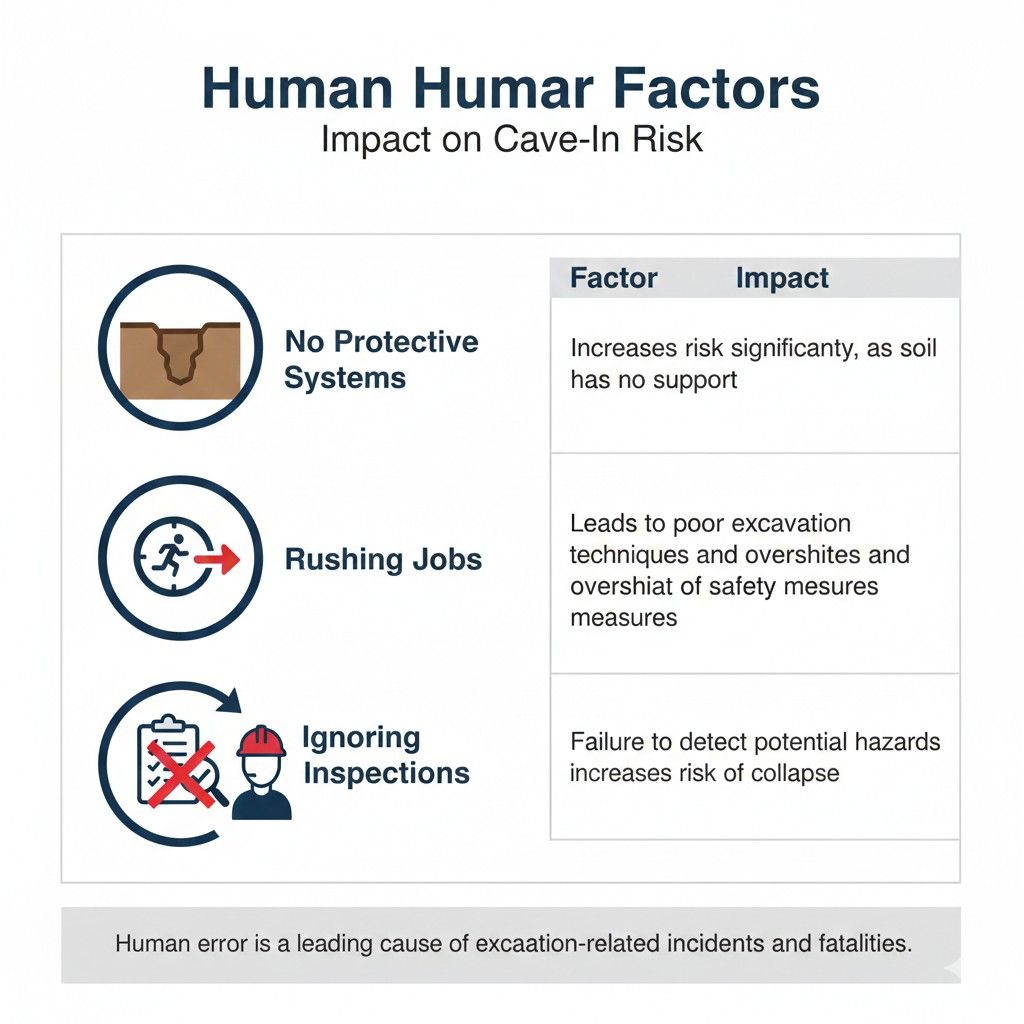

Human Error and Poor Planning

While soil and environmental factors play a major role in cave-ins, human error and poor planning are also common causes of excavation accidents.

- No Protective Systems: One of the leading causes of cave-ins is the failure to implement protective systems, such as trench boxes, shoring, or sloping. These systems are designed to hold back the soil and prevent a collapse, but they are often neglected due to time constraints or poor planning.

- Rushing Jobs: Sometimes, workers or supervisors feel pressure to complete the job quickly, leading them to skip important safety steps. Rushing can result in improper excavation techniques, insufficient support systems, or inadequate safety measures, all of which increase the risk of a cave-in.

- Ignoring Inspections: Proper inspection is key to ensuring excavation safety. Excavations should be inspected regularly for signs of weakness or instability. However, in some cases, inspections are overlooked, or workers fail to notice the early warning signs of a potential collapse, such as cracks in the trench walls or shifting soil.

| Human Error Factors | Impact on Cave-In Risk |

|---|---|

| No Protective Systems | Increases risk significantly, as soil has no support |

| Rushing Jobs | Leads to poor excavation techniques and oversight of safety measures |

| Ignoring Inspections | Failure to detect potential hazards increases risk of collapse |

Cave-ins are a major hazard in excavation work, and they happen so often because of a combination of soil types excavation safety issues, environmental factors, and human error.

Unstable soil excavation areas, such as wet clay or loose sand, are more likely to collapse, especially in the face of poor weather, vibrations, or nearby traffic. Human errors, such as not using proper protective systems or rushing jobs, only add to the danger.

By understanding these risks and implementing the right safety measures, such as trench boxes and proper soil stabilization techniques, the likelihood of cave-ins can be dramatically reduced, making excavation work safer for everyone involved.

See also 2 Bedroom Cabin With Loft Floor Plans

OSHA Regulations on Excavation Safety

Excavation work is one of the most hazardous activities in construction, and ensuring safety on excavation sites is critical. The OSHA excavation requirements are designed to protect workers from serious injuries or fatalities related to cave-ins, falls, and other excavation-related risks.

These regulations help to create safer work environments by setting standards for excavation practices and requiring protective systems. In this section, we’ll explore the key aspects of OSHA’s regulations on excavation safety and the role of the competent person excavation.

OSHA Excavation Standards (29 CFR 1926 Subpart P)

OSHA has established specific standards for excavation work under 29 CFR 1926 Subpart P, which outlines the legal requirements for excavation safety in the construction industry. These regulations are designed to minimize excavation hazards and protect workers from injury.

- Legal requirements: According to OSHA excavation requirements, employers must follow specific regulations when working in or around excavation sites. This includes ensuring that trenches or excavations are properly inspected, supported, and maintained. Employers are required to take the necessary steps to protect workers from hazards, including cave-ins, falling loads, toxic gases, and water accumulation.

- Employer responsibilities: Employers have a legal obligation to provide a safe work environment and ensure that workers are properly trained on excavation safety. Employers must:

- Provide proper protective systems like trench boxes, shoring, or sloping to prevent cave-ins.

- Conduct regular inspections of excavation sites to identify hazards.

- Implement safety measures to control or eliminate risks such as falls, toxic gases, and flooding.

- Ensure workers are equipped with necessary personal protective equipment (PPE), such as helmets, gloves, and safety boots.

- Keep clear access and egress routes for workers to safely enter and exit the excavation site.

By adhering to these regulations, employers can significantly reduce the risk of accidents and ensure that workers are safe while performing excavation tasks.

Role of the Competent Person

One of the most crucial elements in excavation safety is the role of the competent person excavation. According to OSHA, a competent person is someone who is trained, experienced, and authorized to identify hazards and take corrective action on excavation sites.

- Daily inspections: A competent person is responsible for conducting daily inspections of excavation sites to identify any potential hazards. This includes checking for signs of soil instability, water accumulation, or damage to protective systems. Inspections should be done before work begins each day and throughout the day as conditions change.

- Soil classification: Proper soil classification is critical in excavation safety. A competent person must assess the soil type and determine the appropriate support system based on the soil’s properties. Understanding whether the soil is stable or unstable helps in selecting the correct protective measures. This is especially important in areas where the soil might be prone to collapse, such as loose sand or wet clay.

- Hazard recognition: The competent person must be able to recognize various excavation hazards, including but not limited to:

- Cave-ins, which are the most significant risk in excavation.

- Fall hazards due to unprotected edges or improper barriers.

- Hazardous atmospheres, including the presence of toxic gases or low oxygen levels.

- Water accumulation or flooding risks.

By recognizing these hazards, the competent person can take immediate action to prevent accidents, such as adjusting the trench’s support system or halting work if unsafe conditions are present.

| OSHA Requirements | Common Violations |

|---|---|

| Proper protective systems in place | Failure to install trench boxes or shoring |

| Daily inspections by a competent person | Lack of daily inspections or incomplete checks |

| Soil classification and stability assessment | Misclassification of soil types or ignoring instability |

| Clear access/egress routes for workers | Blocking entry/exit paths or inadequate routes |

| Adequate fall protection | Missing barriers or unguarded edges |

OSHA excavation requirements provide clear and essential regulations to ensure the safety of workers on excavation sites. Employers are legally required to follow these standards, providing proper protective systems, conducting daily inspections, and ensuring the site is safe for workers.

The competent person excavation plays a crucial role in ensuring that these standards are met by identifying and addressing hazards before they become serious risks.

By adhering to these OSHA regulations and recognizing common violations, employers can create a safer work environment and reduce the chances of accidents and injuries on excavation sites.

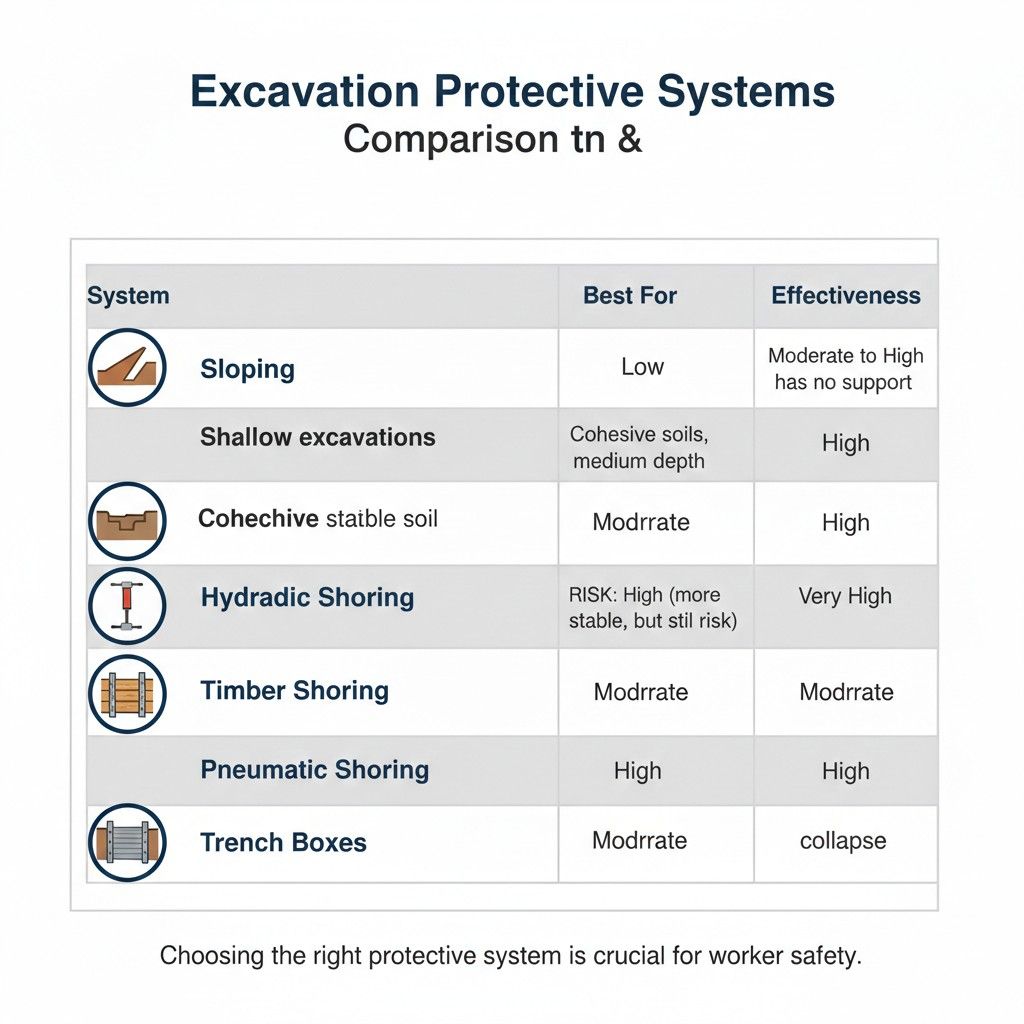

Protective Systems Used to Prevent Cave-Ins

Cave-ins are a major hazard in excavation work, but the good news is that there are several protective systems in place to prevent them. These systems are designed to support the walls of an excavation and prevent the soil from collapsing, ensuring the safety of workers.

In this section, we will explore four key protective systems used in excavation: sloping, benching, shoring, and shielding (trench boxes).

Sloping

Sloping is one of the simplest and most effective methods to prevent cave-ins. It involves cutting the walls of the excavation at an angle to reduce the pressure on the soil and prevent it from collapsing.

- Angles: The angle of the slope is determined based on the soil type and other factors, such as weather conditions. For example, a common rule is a 1:1 ratio, meaning for every foot of depth, the wall of the excavation should be cut back one foot. However, steeper slopes are possible in certain conditions.

- Soil types: Different soils require different angles for sloping. Stable soils, like clay, may allow for steeper slopes, while loose or sandy soils may require a gentler slope. If the soil is loose or unstable, the slope needs to be less steep to reduce the likelihood of a collapse.

- When it works: Sloping is an effective method in shallow excavations where the soil is relatively stable. It is commonly used for trenching and general excavation tasks, especially in less deep areas where large protective systems may not be needed.

Sloping is often considered the simplest and least costly protective system, but it may not always be feasible for deeper or more complex excavation sites.

Benching

Benching is another protective system that involves creating step-like cuts in the sides of an excavation. These cuts reduce the vertical height of the walls, making it harder for the soil to collapse.

- Step-like cuts: Benching creates a series of steps, which distribute the pressure from the excavation across multiple levels. The horizontal steps are designed to prevent the collapse of large sections of soil, allowing the worker to work more safely in the trench.

- Limitations: While benching can be highly effective, it is not suitable for all soil types or excavation depths. For instance, it works best in cohesive soils like clay but may not be effective in loose, granular soils such as sand. Additionally, benching requires sufficient space at the top of the excavation for the steps to be cut back, which limits its use in narrow trenches.

Shoring

Shoring is a protective system that involves the use of various materials to brace the sides of an excavation and prevent cave-ins.

- Hydraulic shoring: Hydraulic shoring uses hydraulic-powered supports to brace the sides of the excavation. This system is adjustable, allowing it to be used in various depths and soil types. It is one of the most commonly used systems for deeper excavations due to its strength and ease of use.

- Timber shoring: Timber shoring involves the use of wood to create braces or beams across the excavation to prevent the soil from collapsing. While it is effective, it is often less reliable than hydraulic or pneumatic shoring and may require more maintenance.

- Pneumatic shoring: Pneumatic shoring involves using air pressure to support the sides of the excavation. This system is commonly used for medium to deep excavations, offering a good balance between ease of installation and effectiveness.

Shoring is effective in deeper excavations where sloping or benching would not be practical. It can also be used in areas where space is limited and when quick installation is required.

Shielding (Trench Boxes)

Shielding, often referred to as trench boxes, is a protective system designed to protect workers from cave-ins by creating a barrier between them and the soil.

- How they work: Trench boxes are large, metal or plastic structures placed inside the excavation to protect workers. They surround the workers, allowing them to work safely within the trench while the walls of the excavation remain unsupported. These boxes are usually placed in trenches where soil is unstable and where other protective systems, like sloping or shoring, are not suitable.

- Common misconceptions: One common misconception is that trench boxes are a foolproof solution. However, they are not designed to hold back massive amounts of soil, especially in extremely deep excavations. They are best used for shallow to medium-depth trenches and require proper installation and maintenance to ensure they work effectively.

| System | Best For | Cost | Effectiveness |

|---|---|---|---|

| Sloping | Shallow excavations, stable soil | Low | Moderate to High |

| Benching | Cohesive soils, shallow to medium depth | Moderate | High |

| Hydraulic Shoring | Deep excavations, unstable soils | High | Very High |

| Timber Shoring | Shallow to medium depth, stable soils | Moderate | Moderate |

| Pneumatic Shoring | Medium to deep excavations | High | High |

| Trench Boxes | Shallow to medium depth, unstable soils | High | Very High |

Protective systems such as sloping, benching, shoring, and shielding (trench boxes) play a vital role in preventing cave-ins and ensuring the safety of workers. Each system has its advantages and limitations depending on the soil type, excavation depth, and project requirements.

By choosing the appropriate system and ensuring proper installation, employers can create safer excavation sites and reduce the risk of accidents. Whether using simple sloping for shallow trenches or hydraulic shoring for deep excavations, these protective systems are essential to excavation safety.

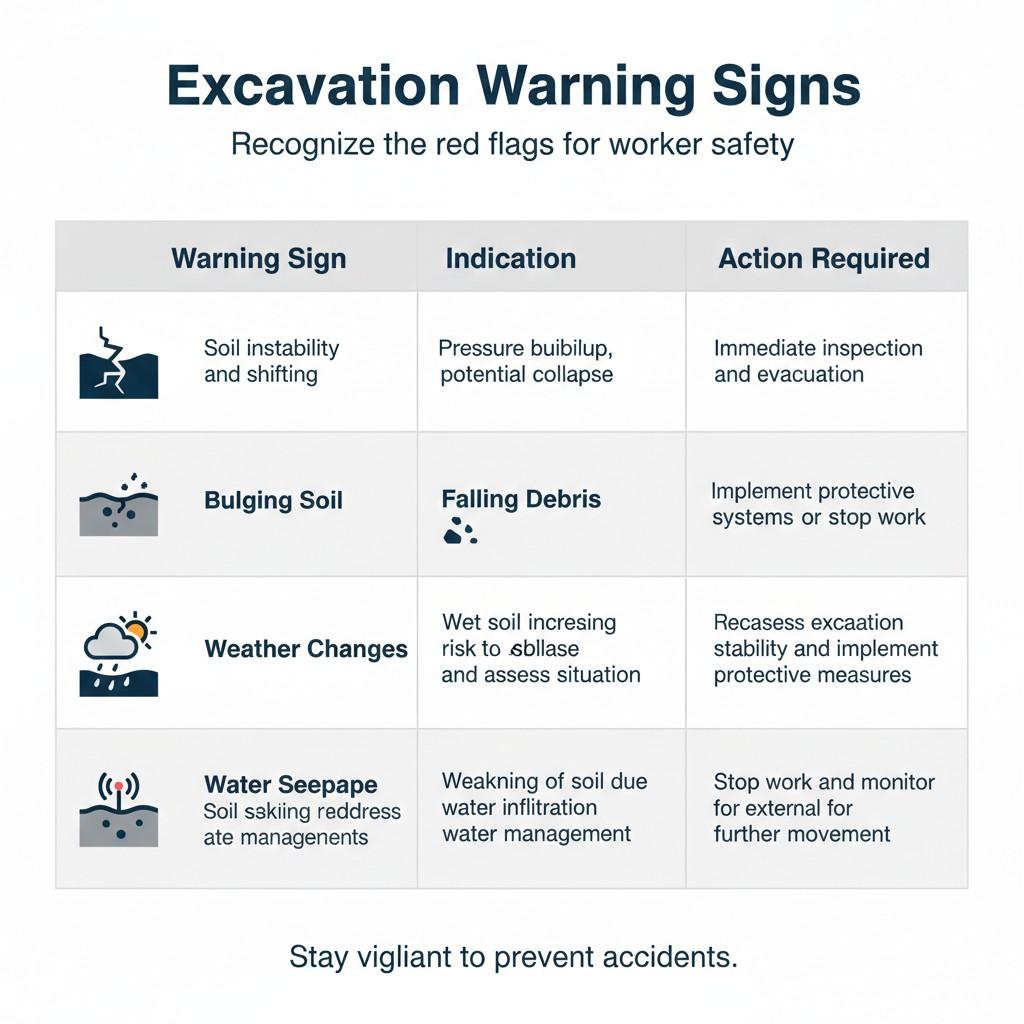

Warning Signs of an Impending Cave-In

Cave-ins are one of the most serious risks associated with excavation work, and being able to identify the cave-in warning signs is crucial for preventing accidents.

Knowing what to look for, both visually and environmentally, can help workers and supervisors take action before a collapse occurs. In this section, we’ll explore the key excavation danger signs that can indicate an impending cave-in.

Visual Warning Signs

The first indicators of a possible cave-in are often visible on the surface of the excavation site. These signs can be detected through regular inspections, helping workers recognize danger early.

- Cracks: One of the most obvious cave-in warning signs is the appearance of cracks along the walls or floor of the excavation. These cracks signal that the soil is becoming unstable and may give way at any moment. Cracks can appear horizontally or vertically, and their size or depth can indicate the severity of the instability.

- Bulging soil: Bulging or heaving soil around the edges of the excavation is another warning sign. This happens when the pressure inside the trench causes the walls to swell or bulge outwards. This indicates that the trench is becoming compromised, and a collapse could occur if the pressure continues to build.

- Falling debris: If small amounts of soil or rocks begin falling into the excavation, it’s a clear sign that the walls are weakening. Falling debris can also indicate that the ground is shifting, which means the excavation is at risk of caving in. Workers should immediately evacuate if this happens and assess the situation.

Environmental Clues

In addition to visual signs, environmental changes can also serve as early warnings of a potential cave-in. These changes can be due to external conditions such as weather, water, or vibrations.

- Weather changes: Sudden weather changes, especially heavy rainfall or storms, can increase the risk of cave-ins. Wet soil becomes heavier and more likely to collapse. If the weather changes abruptly, it’s essential to inspect the excavation and take appropriate safety measures, like shoring or sloping, to prevent accidents.

- Water seepage: The appearance of water seepage in or around the excavation site is another clear warning sign. Water can weaken the soil and lead to shifting, making the excavation unstable. Groundwater or runoff from nearby rain can also increase the likelihood of a collapse. If water begins to seep into the excavation, workers should stop work and reassess the site’s stability.

- Vibrations: Vibrations from nearby traffic, heavy machinery, or construction activities can destabilize the excavation. These vibrations can cause the soil to shift or loosen, leading to a potential collapse. Workers should be cautious when vibrations occur and monitor the excavation site closely for any changes in soil stability.

| Warning Sign | Indication | Action Required |

|---|---|---|

| Cracks | Soil instability and shifting | Immediate inspection and evacuation |

| Bulging Soil | Pressure buildup, potential collapse | Implement protective systems or stop work |

| Falling Debris | Soil movement or instability | Evacuate the trench and assess situation |

| Weather Changes | Wet soil increasing risk of collapse | Reassess excavation stability and implement protective measures |

| Water Seepage | Weakening of soil due to water infiltration | Stop work and address water management |

| Vibrations | Soil disturbance due to external forces | Stop work and monitor for further movement |

Recognizing excavation danger signs early can prevent fatal accidents caused by cave-ins. Visual signs like cracks, bulging soil, and falling debris are often the first indications that the soil is becoming unstable.

Environmental factors such as weather changes, water seepage, and vibrations can also contribute to an increased risk of cave-ins.

By staying vigilant and acting quickly when these signs are observed, workers and employers can significantly reduce the chances of a collapse, ensuring a safer excavation site. Always be alert to these cave-in warning signs, and prioritize safety to protect workers.

Real-Life Excavation Accidents and Case Studies

Excavation work is inherently dangerous, and real-life case studies and accidents provide valuable insights into why tragedies occur and how they could have been prevented.

By studying common patterns in fatal incidents and analyzing lessons learned from OSHA reports, we can better understand how to protect workers in future excavation projects.

Common Patterns in Fatal Incidents

Several common patterns emerge in fatal excavation accidents, and recognizing these patterns can help in identifying risks before they become fatal.

- No protection: One of the most consistent patterns in fatal excavation accidents is the lack of protective systems such as trench boxes, shoring, or sloping. When excavations are not properly supported, the likelihood of a cave-in increases dramatically. Protective systems are crucial to keeping workers safe from collapsing soil, but they are often overlooked due to time constraints, cost-saving measures, or a lack of awareness.

- Short-duration jobs: Excavation accidents are more likely to occur on short-duration jobs where safety measures are compromised in favor of speed. In these cases, workers may not take the necessary precautions or conduct proper inspections before beginning work. The rush to complete the task quickly can lead to insufficient safety measures, increasing the chances of a collapse.

- Lack of inspections: Failing to inspect the excavation site regularly is another common factor in excavation accidents. Without routine inspections, problems such as unstable soil, water accumulation, or small cracks can go unnoticed, and the site may become increasingly dangerous over time. Regular inspections are essential to identifying potential hazards and correcting them before they lead to catastrophic events.

Lessons Learned From OSHA Reports

Case studies from OSHA reports have highlighted what went wrong in many fatal excavation accidents and what measures could have saved lives.

- What went wrong: In many incidents, workers were not properly protected from cave-ins or other hazards. For example, a case in which workers were buried in a trench occurred because the excavation lacked shoring systems. Additionally, workers were often working in confined spaces without adequate ventilation or protection from hazardous atmospheres, leading to suffocation or toxic exposure.

- What could have saved lives: The primary lessons learned from these cases are the importance of using protective systems, conducting regular inspections, and ensuring proper worker training. Proper planning before digging, including soil testing, utility marking, and weather checks, could also have identified potential hazards early on and helped prevent the accidents. Lastly, maintaining strict safety protocols and encouraging a culture of safety on-site could have avoided these tragedies.

How to Reduce the Greatest Danger in Excavations

The greatest danger in excavations is the risk of cave-ins, but there are several measures that can be taken to reduce this risk and protect workers.

By focusing on planning before digging, daily safety procedures, and effective emergency response, the likelihood of a cave-in can be greatly minimized.

Planning Before Digging

- Soil testing: Before starting any excavation project, it’s essential to conduct thorough soil testing. Different soil types have different stability levels, and understanding the type of soil in the excavation area helps in determining the appropriate protective measures. Soil testing also allows workers to assess whether the soil is prone to shifting, becoming saturated with water, or collapsing under pressure.

- Utility marking: Utility lines, such as water, gas, and electricity, pose a significant risk during excavation work. Utility marking before digging ensures that workers are aware of the locations of these lines, which can help prevent accidental damage and reduce the risk of explosions, electrocution, or flooding. Proper utility marking is an essential step in safe excavation practices.

- Weather checks: Weather plays a critical role in the stability of the excavation site. Heavy rainfall or extreme temperatures can increase the likelihood of soil instability or flooding. Checking the weather forecast regularly and postponing excavation work during adverse weather conditions can significantly reduce the risk of cave-ins and other accidents.

Daily Safety Procedures

- Inspections: Daily inspections are crucial to ensuring the safety of the excavation site. A competent person should conduct regular inspections to check for signs of instability, such as cracks in the soil, water accumulation, or loose materials. If any hazards are identified, work should be stopped immediately, and corrective measures should be taken.

- Worker training: Proper training is vital to ensuring that workers understand the risks involved in excavation and how to mitigate them. Workers should be educated about cave-in warning signs, protective systems, and emergency procedures. Additionally, workers should be trained to use equipment safely and know how to recognize unstable soil conditions.

- Emergency planning: Every excavation site should have a detailed emergency response plan in place. This plan should include clear procedures for evacuating workers, contacting emergency responders, and providing first aid if needed. An emergency response team should be trained and equipped to act quickly in the event of a cave-in or other excavation-related accidents.

Emergency Response to Cave-Ins

- Why rescue is dangerous: Rescue operations in the event of a cave-in are incredibly dangerous. The risk of secondary collapses increases during rescue attempts, and untrained workers can put themselves at risk by trying to assist victims. Only trained professionals should attempt rescue operations, and they should do so with caution.

- Calling professionals: When a cave-in occurs, it’s crucial to call professional rescue teams immediately. These teams are equipped with the necessary tools and expertise to safely recover workers from collapsed trenches and provide medical care if needed.

- Never entering collapsed trenches: In the event of a cave-in, workers should never attempt to enter the collapsed trench without proper protective measures. The risk of further collapse is high, and entering the trench can make the situation worse. Instead, workers should evacuate the area and wait for trained rescue personnel to arrive.

| Prevention Measure | Action | Effectiveness |

|---|---|---|

| Soil Testing | Assess soil stability and select appropriate safety systems | High |

| Utility Marking | Identify and avoid utility lines to prevent accidents | High |

| Weather Checks | Monitor weather conditions to prevent unstable conditions | Moderate to High |

| Daily Inspections | Ensure the site is safe and identify hazards early | Very High |

| Worker Training | Educate workers on safety protocols and risks | Very High |

| Emergency Planning | Prepare for accidents and ensure swift response | Very High |

Reducing the greatest danger in excavations requires careful planning, daily safety procedures, and a clear emergency response plan.

By conducting soil tests, marking utilities, checking weather conditions, and ensuring daily inspections and worker training, the risk of cave-ins can be significantly reduced.

Furthermore, in the event of a cave-in, proper rescue protocols must be followed to avoid additional harm. Safety is paramount, and these measures will help ensure that workers are protected while performing excavation work.

Excavation Safety Checklist

Ensuring excavation safety requires a methodical approach to identifying and addressing potential hazards. The following checklist can help ensure that all necessary precautions are taken before, during, and after excavation work.

It serves as a guide to prevent accidents and fatalities related to excavation, especially cave-ins, falls, and exposure to hazardous atmospheres.

Daily Excavation Safety Checklist

| Item | Checked |

|---|---|

| Soil classified | ✅ |

| Protective system installed | ✅ |

| Access ladders | ✅ |

| Atmosphere tested | ✅ |

- Soil classified: Before starting work, the type of soil must be classified to determine the appropriate protective systems (such as shoring, sloping, or trench boxes). The soil’s stability is critical in determining the risk of cave-ins.

- Protective system installed: A protective system, such as trench boxes, shoring, or sloping, must be installed to support the walls of the excavation and prevent cave-ins. This system should be in place before workers enter the excavation area.

- Access ladders: Safe access and egress routes are essential for workers to enter and exit the excavation site. Ladders or steps should be properly placed and accessible to ensure workers can quickly and safely leave the site in case of an emergency.

- Atmosphere tested: The atmosphere within the excavation should be tested for hazardous gases, such as methane, hydrogen sulfide, or low oxygen levels. If dangerous gases are detected, ventilation or respiratory protection should be provided.

By following this excavation safety checklist, employers and workers can ensure that all essential safety precautions are in place, reducing the risk of accidents and injuries on the job site. Regular checks and ongoing awareness are key to maintaining a safe excavation environment.

Frequently Asked Questions About Excavation Dangers

Excavation work involves a variety of risks, and understanding these dangers is crucial for preventing accidents. Below are some common questions about excavation safety and the risks involved.

Which of these is known as the greatest danger associated with excavations?

The greatest danger associated with excavations is undoubtedly cave-ins. A cave-in occurs when the walls or sides of an excavation collapse, burying workers under tons of soil.

This can be extremely dangerous, as workers can be trapped, suffocated, or crushed. Cave-ins are the leading cause of fatalities in excavation work and are considered the most deadly risk in construction and excavation sites.

Why are trench cave-ins so dangerous?

Trench cave-ins are particularly dangerous due to the rapid speed at which they can occur. The soil in trenches is often unstable and can collapse without warning.

The weight of the soil can be immense—up to 3,000 pounds per cubic yard—making it nearly impossible for a trapped worker to escape.

In addition, the confined nature of trenches makes it difficult for rescue operations to take place, increasing the likelihood of fatality. These factors combined make trench cave-ins one of the most hazardous situations in excavation work.

At what depth do OSHA excavation rules apply?

OSHA’s excavation rules, specifically under 29 CFR 1926 Subpart P, apply to excavations that are five feet deep or more. These regulations are designed to protect workers from the dangers of cave-ins and other excavation hazards.

While the rules are mandatory for excavations over five feet deep, employers are encouraged to implement safety measures for shallower trenches as well, as accidents can occur at any depth.

Can short excavations still collapse?

Yes, short excavations can still collapse, even if they are shallow. While deeper excavations are generally considered higher-risk, the soil in a short excavation may still be unstable, and factors such as weather, nearby vibrations, or improper shoring can cause a collapse.

Regardless of depth, excavations must always be treated with caution, and proper protective systems must be in place to prevent accidents.

Who is responsible for excavation safety?

Employers are primarily responsible for ensuring excavation safety. They must ensure that safety measures are in place, including providing proper protective systems (such as shoring, sloping, or trench boxes), conducting inspections, and offering worker training.

However, the competent person, an individual designated to assess and manage excavation safety, plays a critical role in overseeing site conditions, recognizing hazards, and implementing safety measures. Ultimately, both employers and competent persons are responsible for ensuring safety on excavation sites.

Final Answer – The Greatest Danger Associated With Excavations Explained

When it comes to excavation safety, the greatest danger associated with excavations is a cave-in. Cave-ins are the leading cause of fatalities in excavation work, making it the most serious threat on construction sites.

Key Takeaways

- Cave-ins are the #1 killer: Cave-ins remain the deadliest risk in excavation work, claiming numerous lives every year. They happen quickly and without warning, making them especially dangerous for workers who may not have time to react.

- They happen fast and without warning: The collapse of soil in an excavation can occur rapidly, often within seconds. Workers may not realize the danger until it’s too late, making immediate response crucial to survival.

- Protective systems save lives: Protective systems like trench boxes, shoring, and sloping are essential in preventing cave-ins. These systems provide physical barriers that support the soil and prevent it from collapsing, greatly reducing the risk of accidents.

- OSHA rules exist for a reason: The OSHA excavation rules are designed to ensure the safety of workers by providing clear guidelines on excavation practices. Compliance with these regulations can save lives by minimizing hazards such as cave-ins, falls, and exposure to dangerous atmospheres.

| Hazard | Risk Level |

|---|---|

| Cave-ins | Extreme |

| Falls | High |

| Hazardous air | High |

| Water | Medium |

In conclusion, cave-ins are the most dangerous risk on excavation sites, and preventing them requires the use of protective systems, strict adherence to safety regulations, and vigilance on the part of both employers and workers.

Following OSHA excavation requirements, conducting regular inspections, and ensuring that workers are well-trained can significantly reduce the likelihood of cave-ins and other excavation-related accidents. Safety on excavation sites is not just about compliance—it’s about protecting lives.